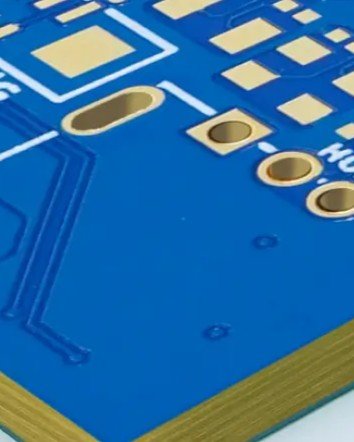

A Complete Guide to FR4 Material, Properties, Applications, and Manufacturing Printed Circuit Boards (PCBs) are the foundation of modern electronics, and among all PCB materials, FR4 remains the most widely used and trusted option. Whether you are designing consumer electronics, industrial…

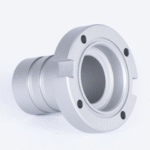

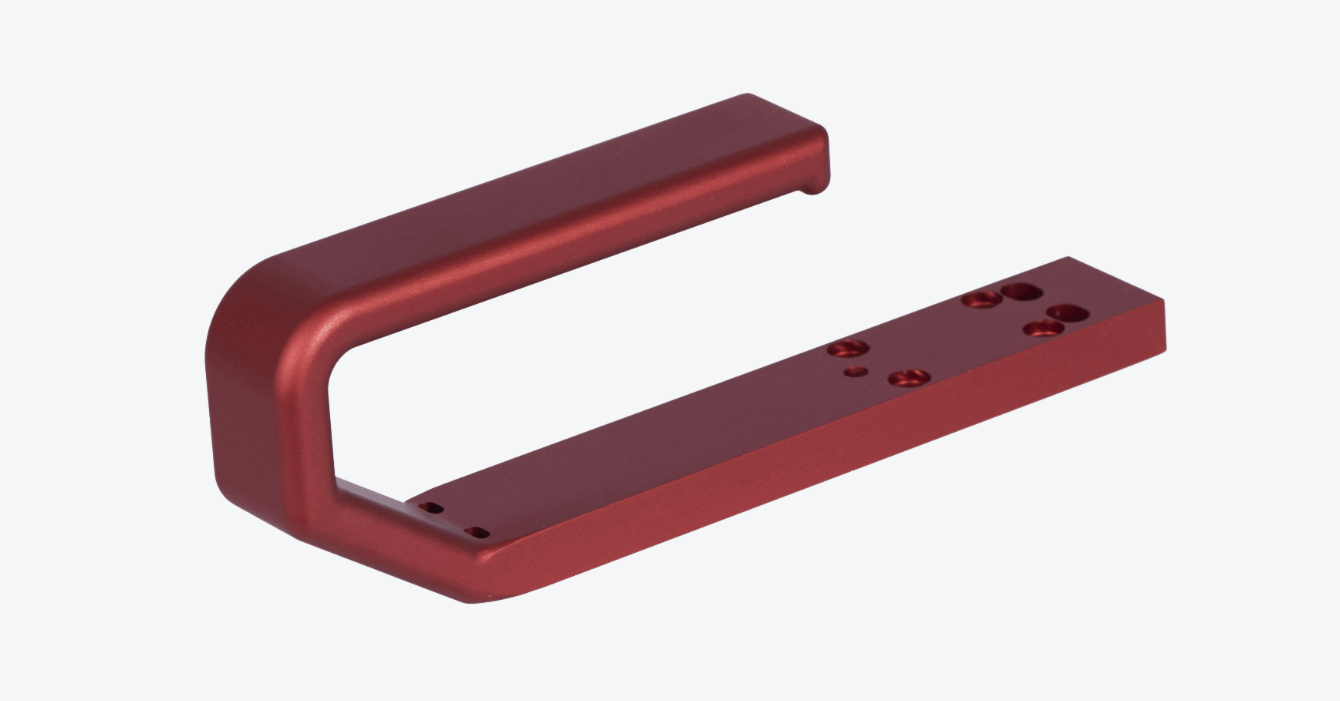

Aluminum 7075 CNC Machining

7075 aluminum alloy is a cold-treated forging alloy with high strength, far better than soft steel. 7075 is one of the most powerful alloys for commercial use. 7075 aluminum alloy has a tight structure and strong corrosion resistance and is best…

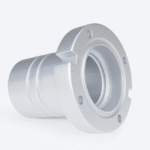

Aluminum 6061 CNC Machining

6061(T6) aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process.6061 aluminum material belongs to heat-treatable strengthening alloys, with good formability, weldability, and machinability. It has medium strength and can maintain good operability after annealing. The…

How to Learn CNC Programming: A Step-by-Step Guide for Beginners

CNC programming plays a vital role in modern manufacturing. Learning CNC programming may seem complicated at first, but with the right methods, anyone can master it step by step. This article provides detailed guidance to help you get started and accelerate…

Understanding CNC Machine Tolerances and Their Impact on Part Accuracy

In precision manufacturing, CNC machine tool tolerance is a core indicator of part quality, directly affecting assembly performance, functional reliability, and product service life. Whether for aerospace components or medical devices, strict tolerance control is key to competitiveness. This article analyses…

From CAD to CNC The Importance of Accurate 3D Modeling in Manufacturing

In modern manufacturing, the process from CAD design to CNC machining is indispensable for producing high-quality parts and products. 3D modelling, as a core part of this process, directly impacts the accuracy, functionality, and appearance of the final product. This article…

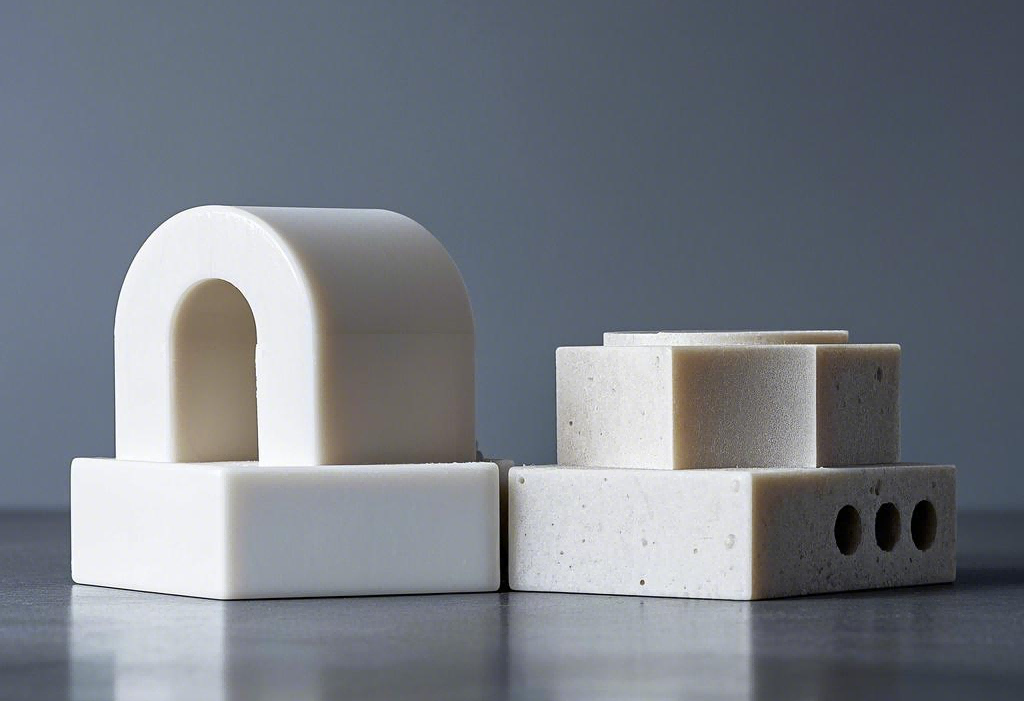

Are There Any Design Limitations or Restrictions for CNC Machining

Size and Shape Constraints CNC machines have physical limitations regarding the size and shape of machinable parts. The machine’s work envelope determines the maximum allowable dimensions. In addition, certain complex geometries—such as deep cavities or narrow internal channels—may be difficult or…

Sheet Metal vs CNC Machining: A Guide to Choosing the Right Method for Your Metal Parts

When it comes to fabricating metal parts, manufacturers often face a key decision: sheet metal fabrication or CNC machining. Each method has its own strengths, and the right choice depends on factors such as part complexity, precision requirements, cost structure, and…

Surface Finish in Machining, Types, Charts & Testing

What is Surface Finish in Machining? At its core, surface finish in machining refers to the small-scale irregularities left on the surface of a part after machining. These irregularities are typically grouped into three categories: Now picture two extremes: That balance…

What Steps Are Taken To Minimize Waste In CNC Machining Processes?

Design optimization, material management, strategic machining, tool maintenance, and waste recycling minimize waste in CNC machining. Waste in CNC machining refers to surplus or residual material produced during the machining process. Waste can take many different forms, including chips, shavings, scraps,…