When it comes to fabricating metal parts, manufacturers often face a key decision: sheet metal fabrication or CNC machining. Each method has its own strengths, and the right choice depends on factors such as part complexity, precision requirements, cost structure, and production volume.

At prysen, we help customers select the most efficient manufacturing route based on real production needs. Below is a clear breakdown to help you make an informed decision.

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing process that shapes flat metal sheets into finished components or products. Common materials include steel, aluminum, stainless steel, brass, and copper.

Key Steps in Sheet Metal Fabrication

- Cutting

Metal sheets are cut to size using shears, laser cutting, or CNC plasma cutting equipment. - Bending

Press brakes and bending machines form the metal into required angles and curves. - Forming

Additional processes create features such as flanges, beads, and embossing. - Joining

Components are assembled using welding, fasteners, or industrial adhesives. - Finishing

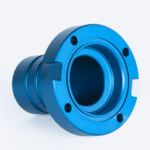

Surface treatments such as painting, powder coating, or anodizing enhance appearance and corrosion resistance.

Sheet metal fabrication is widely used in automotive, construction, electronics, aerospace, and industrial equipment manufacturing. It is ideal for producing strong, lightweight, and repeatable metal components.

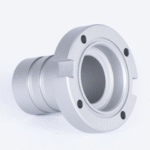

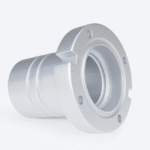

What Is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that removes material from a solid workpiece to produce precise parts. Using CAD and CAM software, CNC machines follow programmed instructions to control cutting tools with high accuracy.

CNC machining is known for:

- Tight tolerances

- Complex geometries

- Excellent repeatability

- Wide material compatibility

Key Factors Influencing the Choice

1. Part Complexity & Precision

- Sheet Metal Fabrication: Best for simple to moderately complex parts.

- CNC Machining: Ideal for intricate designs and high-precision requirements.

2. Cost Considerations

- Sheet Metal Fabrication: More cost-effective for large-volume production.

- CNC Machining: Higher unit cost, especially for complex or low-quantity parts.

3. Lead Time & Production Volume

- Sheet Metal Fabrication: Shorter lead times for high-volume, simple components.

- CNC Machining: Suitable for prototyping, low-volume production, and custom parts.

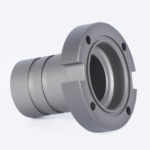

4. Material Options

- Sheet Metal Fabrication: Primarily sheet metals such as steel and aluminum.

- CNC Machining: Metals, plastics, composites, and engineering materials.

Combining Sheet Metal Fabrication and CNC Machining

Many manufacturers achieve the best results by combining both methods. For example:

- Sheet metal fabrication for structural or enclosure components

- CNC machining for precision features, prototypes, or tight-tolerance parts

At prysen, this hybrid approach helps balance cost efficiency with precision performance.

Conclusion

Choosing between sheet metal fabrication and CNC machining directly impacts product quality, cost efficiency, and production speed. By evaluating part complexity, tolerance requirements, material selection, and production volume, manufacturers can select the optimal process with confidence.

Whether you need high-volume sheet metal components or precision-machined CNC parts, prysen delivers manufacturing solutions tailored to your exact requirements.