CNC programming plays a vital role in modern manufacturing. Learning CNC programming may seem complicated at first, but with the right methods, anyone can master it step by step. This article provides detailed guidance to help you get started and accelerate your career in manufacturing.

What is CNC Programming?

CNC programming is a set of instructions that tell a CNC machine how to move a tool and cut or shape material.

- G-code controls operations such as tool movement and machining trajectories.

- M-code controls auxiliary machine functions, like starting/stopping spindles or tool changes.

Programmers convert part designs into actionable instructions, directing the CNC machine to create precise parts.

Learn the Basics of CNC Programming

Understanding machine types (mills, lathes, 5-axis machines) requires mastering G-code and M-code.

Common G-codes:

G00: Rapid positioningG01: Linear interpolationG02/G03: Circular interpolation

Common M-codes:

M03: Turn on spindleM05: Stop spindleM06: Tool change

Mastering these codes forms the foundation of CNC programming.

Learn to Use CNC Programming Software

Modern CNC programming increasingly relies on software tools such as Mastercam, Fusion 360, SolidCAM, which help with:

- Part modeling

- Toolpath generation

- Program writing

Learning tip: Start with simple projects, like programming a round part, and gradually explore more advanced features to optimize programming efficiency.

Understanding the CNC Machining Process

1. Overall Process

CNC machining begins with a 3D design. The programmer writes an accurate program based on part dimensions, tolerance requirements, and the chosen machining method (milling, turning, etc.), including tool selection and cutting parameters.

2. Accuracy and Tolerance

Every part dimension must adhere strictly to design specifications. CNC programs must account for tolerance requirements to ensure each step achieves the desired precision.

3. Common Machining Problems and Solutions

- Tool wear, excessive cutting forces, rough surfaces

- Solve by adjusting toolpaths, modifying cutting parameters, or selecting the correct tool.

- Example: Optimizing feed rate and depth of cut reduces cutting forces, prolongs tool life, and improves efficiency.

How to Improve CNC Programming Skills

1. Practice and Experience

CNC programming is highly practical. Theoretical knowledge is necessary, but hands-on practice is essential. Working on different projects helps quickly improve skills.

2. Simulation and Virtual Programming

Simulation software (e.g., GibbsCAM, Vericut) allows programmers to:

- Verify program correctness

- Optimize toolpaths

- Reduce errors in actual machining without wasting material

3. Learn from Industry Experts

Join online courses, training sessions, or forums to learn from experienced engineers and stay updated on industry trends. Continuous practice and learning are key to mastery.

Selecting CNC Programming Training Courses and Resources

1. Online Courses and Tutorials

Platforms offer courses suitable for beginners to advanced learners.

2. Books and Documentation

Classic references like CNC Programming Handbook cover G-code, M-code, and solutions to common real-world problems.

3. Industry Certifications

Certifications such as NIMS (National Institute for Metalworking Skills) validate CNC programming skills and are valued by manufacturing employers.

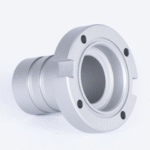

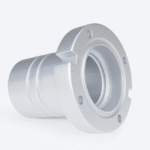

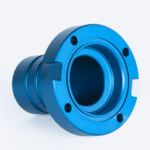

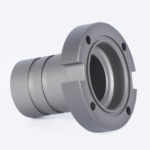

prysen’s Technological Advantage

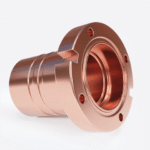

prysen, a leading CNC machining service provider, leverages extensive industry experience to offer:

- High-precision CNC programming services

- Optimized processes for complex manufacturing projects

- Reliable, high-quality machining solutions for various industries

Conclusion

CNC programming is challenging but rewarding. Beginners should start step by step, mastering G-code, M-code, and CNC programming software, combined with hands-on practice and simulation. Selecting authoritative training resources and certifications ensures skill improvement and better career opportunities.

With practice and continuous learning, CNC programming will remain a critical and valuable skill in modern manufacturing.