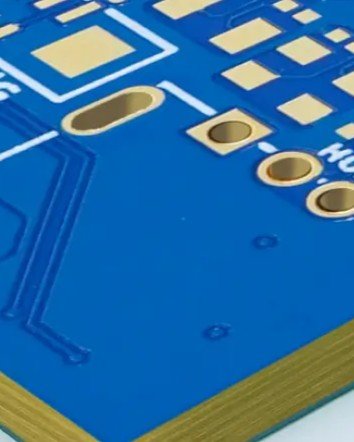

A Complete Guide to FR4 Material, Properties, Applications, and Manufacturing

Printed Circuit Boards (PCBs) are the foundation of modern electronics, and among all PCB materials, FR4 remains the most widely used and trusted option. Whether you are designing consumer electronics, industrial control systems, or automotive devices, understanding FR4 PCB material is essential for making informed design decisions.

This article provides a comprehensive overview of FR4 PCBs, including their structure, properties, thermal behavior, applications, and manufacturing considerations.

What Is FR4 PCB Material?

FR4 stands for Flame Retardant 4, a standard-grade material widely used in PCB manufacturing. It is composed of woven fiberglass cloth reinforced with epoxy resin, designed to meet the UL94 V-0 flammability rating, meaning the material can self-extinguish after ignition.

The fiberglass-reinforced epoxy structure gives FR4 excellent electrical insulation, mechanical strength, and thermal stability, while remaining cost-effective. Because of this balance between performance and affordability, FR4 has become the industry-standard PCB substrate.

FR4 Material Overview

FR4 is classified as a glass-reinforced epoxy laminate with moderate electrical and thermal properties. It is suitable for a wide range of applications, from low-speed circuits to higher-power electronic systems.

Key Electrical Properties

- Dielectric Constant (Dk): Approximately 4.2–4.8 at 1 MHz

- Dissipation Factor (Loss Tangent): Around 0.02 at 1 MHz

These moderate values make FR4 ideal for general-purpose electronic designs, although it is not the best choice for very high-frequency or RF applications above several GHz.

Glass Transition Temperature (Tg) of FR4

The glass transition temperature (Tg) defines how the material behaves under heat and is one of the most critical thermal characteristics of FR4.

FR4 materials are commonly categorized into three Tg ranges:

- Low Tg: 130–140°C

- Standard Tg: 150–160°C

- High Tg: Above 170°C

Higher Tg FR4 materials offer improved thermal stability, making them more suitable for multilayer PCBs, lead-free soldering, and high-temperature operating environments.

Structure and Composition of FR4

FR4 is a composite material made up of several layers, each serving a specific function:

1. Woven Fiberglass Cloth (E-Glass Fibers)

The fiberglass provides mechanical strength and rigidity. Inside the laminate, it appears as a fine woven fabric that resists bending and warping.

2. Epoxy Resin (Flame-Retardant)

The epoxy resin binds the fiberglass layers together, offering excellent electrical insulation and resistance to heat and moisture.

3. Copper Foil (in PCBs)

Copper layers are laminated onto the FR4 substrate using heat and pressure to form conductive traces and planes.

Benefits of FR4 PCB Material

Cost-Effective and Widely Available

Compared to high-performance laminates such as Rogers materials, FR4 is significantly more affordable. Its global availability also makes it ideal for mass production and fast prototyping.

Good Mechanical Strength

The fiberglass reinforcement provides excellent tensile strength and durability, reducing the risk of deformation during manufacturing and assembly.

Reliable Electrical Insulation

FR4 offers stable electrical performance for low- to mid-frequency circuits, ensuring dependable signal isolation and power handling.

How FR4 Thickness Affects PCB Performance

Signal Integrity and Impedance Control

PCB thickness directly affects impedance.

- Thicker FR4 increases dielectric spacing, raising impedance.

- Thinner FR4 reduces spacing and lowers impedance, but dielectric loss still limits high-frequency performance.

For high-speed designs, impedance control is often achieved by adjusting FR4 thickness in combination with trace width and copper weight.

Thermal Management

While FR4 is not a high-thermal-conductivity material, thickness influences heat dissipation. Thicker boards offer better mechanical support but may trap heat, requiring careful thermal design.

Mechanical Stability

Thicker FR4 boards provide greater rigidity, which is important for large PCBs or mechanically stressed applications.

Common Applications of FR4 PCBs

Consumer Electronics

FR4 PCBs are widely used in smartphones, wearables, home appliances, and consumer gadgets due to their balance of cost, durability, and performance.

Industrial Control Systems

Industrial electronics rely on FR4 for stable operation, mechanical strength, and resistance to harsh environments.

Automotive Electronics

From control modules to sensors, FR4 remains a common material choice in automotive PCB designs when extreme RF performance is not required.

FR4 PCB Manufacturing Capabilities

Modern PCB manufacturers support extensive FR4 fabrication options, including:

- Layer Count: 1 to 32 layers

- Board Thickness: 0.2mm to 3.2mm

- Copper Thickness:

- Outer layers: 1oz, 2oz (up to 4.5oz for 2-layer boards)

- Inner layers: 0.5oz, 1oz, 2oz

Advanced Features

- Controlled impedance design

- Blind and buried vias

- Back drilling

- Edge plating and castellated holes

- Countersink holes (90° / 135°)

Why Choose FR4 PCBs?

Cost-Effective Production

FR4 PCBs are ideal for both prototyping and mass production, offering excellent value without sacrificing reliability.

Extensive Manufacturing Flexibility

Supports multilayer designs, various surface finishes, and a wide range of mechanical and electrical specifications.

High Customization

Multiple solder mask colors, copper thickness options, and surface finishes allow FR4 PCBs to meet diverse project requirements.

Fast Global Delivery

Modern PCB manufacturers can deliver FR4 prototypes in as little as 24 hours and ship worldwide.

Frequently Asked Questions About FR4 PCB

What is the dielectric constant of FR4?

FR4 typically has a dielectric constant between 4.2 and 4.8 at 1 MHz, affecting signal speed and impedance.

What is the Tg of FR4 material?

FR4 is available in low, standard, and high Tg versions, ranging from 130°C to over 170°C.

Is FR4 suitable for high-frequency circuits?

FR4 works well for low- to mid-frequency applications but is not ideal for very high-frequency or RF designs due to dielectric loss.

How does FR4 perform in multilayer PCBs?

FR4 is widely used in multilayer PCBs and offers good mechanical stability and manufacturability.

Is FR4 RoHS compliant?

Most modern FR4 materials meet RoHS and environmental compliance standards.

Conclusion

FR4 PCB material continues to dominate the electronics industry because it delivers a reliable balance of performance, durability, and cost efficiency. While it may not replace specialized high-frequency substrates, FR4 remains the go-to choice for the vast majority of electronic applications.

Understanding its properties, limitations, and manufacturing considerations allows designers and engineers to fully leverage the strengths of FR4 in real-world PCB designs.