Size and Shape Constraints

CNC machines have physical limitations regarding the size and shape of machinable parts. The machine’s work envelope determines the maximum allowable dimensions. In addition, certain complex geometries—such as deep cavities or narrow internal channels—may be difficult or impossible to machine accurately.

Before proceeding, please confirm whether your project can be manufactured based on the provided design data. If you have further questions, you may consult prysen, and we will respond in a timely manner.

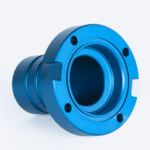

Material Selection

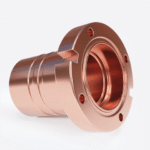

CNC machining is compatible with a wide range of materials, including metals, plastics, and copper alloys. However, machinability varies significantly between materials. Hardened steels and heat-resistant alloys may require specialized tooling and reduced cutting speeds, while softer plastics may deform or melt during machining if parameters are not properly controlled.

Selecting the right material and machining strategy is critical to achieving optimal results.

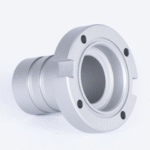

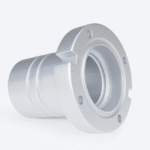

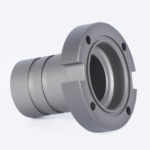

prysen CNC Machining Service

Wall Thickness and Feature Size

While CNC machining can produce highly detailed components, there are practical limits on minimum wall thickness and feature size. Thin walls may vibrate or deflect during machining, leading to dimensional inaccuracies. Extremely small features may also be difficult to achieve due to cutting tool limitations and machine resolution.

Designs should account for these constraints to ensure stable and accurate machining results.

Tool Access

CNC machining relies on cutting tools to remove material from the workpiece. Adequate tool access must be considered during the design stage. Features that are overhanging or difficult to reach may require specialized tools or multiple machining setups, which can increase production complexity and cost.

Undercuts and Overhangs

Standard CNC machining typically approaches the workpiece from above, making undercuts and overhangs challenging to produce. These features often require additional setups or advanced machining techniques such as multi-axis machining.

prysen is equipped with 3-axis, 4-axis, and 5-axis CNC machining capabilities to handle complex geometries and challenging design requirements.

Tolerances and Surface Finish

CNC machining is capable of achieving tight tolerances and high-quality surface finishes. However, extremely strict tolerance requirements or superior surface finish demands can significantly increase machining complexity and cost.

It is recommended to define tolerance and surface finish requirements clearly and evaluate feasibility early in the design phase.