What is Surface Finish in Machining?

At its core, surface finish in machining refers to the small-scale irregularities left on the surface of a part after machining. These irregularities are typically grouped into three categories:

- Roughness: The fine, closely spaced deviations caused by the cutting process itself. Roughness depends heavily on feed rate, tool sharpness, and cutting speed.

- Waviness: Larger, more widely spaced variations caused by machine tool vibration, deflection, or thermal distortion.

- Lay: The direction of the surface pattern, determined by the machining method (e.g., turning leaves circular lay patterns, grinding leaves linear marks).

Now picture two extremes:

- A shaft with poor surface finish that wears down bearings, causes noise, and shortens lifespan.

- A precision aerospace part with a carefully controlled finish that seals tightly, reduces drag, and performs reliably under stress.

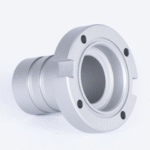

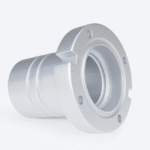

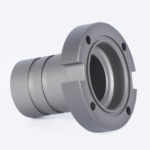

That balance between production speed and finish quality is where experience counts. We see this every day when machining parts for clients across industries. The right finish can make the difference between a part that passes inspection and one that ends up in the scrap bin. At prysen, our advanced machining setups and strict process control mean we don’t have to choose between efficiency and precision, we get both.

Surface Finish Types and Scales

(worthyhardware)

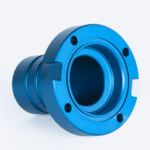

Not every part needs a mirror-like surface. That’s why machinists talk about surface finish types, each suited to a different application:

- Rough machining finish: Produced by fast cutting, typically acceptable for internal features or non-critical surfaces.

- Fine machining finish: Achieved with optimized cutting parameters, often used where moderate precision is needed.

- Ground finish: Obtained with grinding operations, providing tighter tolerances and better smoothness.

- Polished/mirror finish: Achieved through lapping or polishing, critical for medical implants, optics, or sealing components.

Surface Finish Scales

To measure and compare these finishes, engineers use scales such as:

- Ra (Roughness Average): The most common measure, representing average roughness in micrometers (µm) or microinches (µin).

- Rz: Average difference between the highest peak and lowest valley across several samples.

- RMS (Root Mean Square): Another mathematical way to express roughness, slightly different from Ra but often used in older specifications.

At prysen, we don’t just calculate Ra and Rz on paper, we validate them with in-house testing equipment and back it up with real finishing options like bead blasting, anodizing, brushing, and mirror polishing, ensuring that clients get both the numbers and the surface quality their application demands.

In machining, these measurements are often tied to a surface finish scale for machining (sometimes shown as N-numbers, like N1 = super fine, N12 = rough). For example:

- An N7 finish (~0.8 µm Ra) is common on sealing surfaces.

- An N12 finish (~50 µm Ra) is typical for rough milling where accuracy isn’t critical.

Having a standardized surface finish scale for machining allows machinists, engineers, and purchasing managers to “speak the same language” when defining part requirements. And when tolerances come into play, that’s where our team’s experience across both machining and finishing services ensures the final part performs as intended.

Surface Finish Charts & Real Applications

Surface finish is more than a cosmetic choice, in CNC machining, it determines friction, wear resistance, sealing capability, and even how a component interacts with coatings or mating parts. Understanding finish charts, measurement units, and real-world testing methods ensures your parts meet both functional and aesthetic needs. We advise clients on which surface finishes will give them the best balance of function, durability, and cost. Because sometimes a mirror-polished aerospace component makes sense, and sometimes a basic milled finish is all you need. That’s the kind of guidance we bring to every project we handle.

Surface Finish Conversion Chart

Different industries use different metrics for surface roughness. In machining, the most common ones are Ra (average roughness), Rz (mean peak-to-valley height), and N values (grade numbers, mostly ISO-based).

Here’s a conversion table our engineers actually use:

| Roughness Grade (N) | Ra (µm) | Ra (µin) | Typical Process Example |

| N1 | 0.025 | 1 | Superfinishing / Lapping |

| N2 | 0.05 | 2 | Lapping / Honing |

| N3 | 0.1 | 4 | Fine Grinding |

| N4 | 0.2 | 8 | Grinding / Polishing |

| N5 | 0.4 | 16 | Fine Milling / Turning |

| N6 | 0.8 | 32 | Standard Milling / Turning |

| N7 | 1.6 | 63 | General CNC Machining |

| N8 | 3.2 | 125 | Rough Milling |

| N9 | 6.3 | 250 | Rough Turning |

| N10 | 12.5 | 500 | Heavy Cuts, Cast Surfaces |

Curious how these numbers translate to your project? Upload your CAD file and we’ll give you a free surface finish recommendation + quote based on your material and application.

Surface Finish for Stainless Steel

Stainless steel often demands tighter surface finish controls than softer metals, especially in industries like food processing, aerospace, and medical devices. When we machine stainless steel shafts for clients in these industries, a smooth finish isn’t cosmetic, it prevents bacterial build-up and ensures compliance. These are the details we obsess over at prysen.

- 2B Finish (~Ra 0.3–0.5 µm)

- #3 Finish (~Ra 0.8–1.2 µm)

- #4 Finish (~Ra 0.4–0.8 µm)

- #8 Mirror Finish (Ra 0.2 µm or below)

We’ve also found that balancing feed rates with the right tool coating makes all the difference. One medical client came to us with rough implant prototypes, after optimizing parameters, we delivered surfaces smooth enough to pass inspection standards. This is where prysen stands out.

Testing Methods for Surface Finish

Surface roughness isn’t judged by eye alone. For precision requirements, methods include:

| Profilometer | High accuracy |

| Optical | Non-contact measurement |

| Comparator Plates | Quick checks |

| Visual & Tactile | Rough estimation |

How to Achieve the Right Finish

Even the sharpest tools degrade over time. That’s why at prysen, we emphasize tooling maintenance and parameter control.

How we Reduced Roughness by 60% for an Automotive Client

The result: Roughness dropped to Ra 1.2 µm, and the client cut rework costs by nearly 40%. That’s the kind of result we always aim for at prysen.

All in All

Surface finish is where good machining becomes great machining. Here, at prysen, we don’t leave that to chance.